Description

ACRIFIX® TC 0030 is a thinner and cleaning agent for bonding ACRYLITE® acrylic products together. This agent is applied to a product to prepare it for bonding. It can also be used to adjust the viscosity of the cement to create a stronger bond.

- Thinner / Cleaner

- Used to adjust the viscosity of the cement

- Creates a stronger bond

Commonly used to:

- Reduce the viscosity of two-component polymerization adhesives

- Clean adherents to be bonded by means of polymerization adhesives

Technical

Typical Values of Properties

- Viscosity (Brookfield A/60/68°F/20°C):~ 0.6 cp

- Density (68°F/20°C68): ~ 0.94 g/cm3

- Refractive index nD: ~ 1.415

- Color: clear and colorless

- Boiling point: ~ + 212°F/100°C

- Flash point (DIN 51755): ~ + 50°F/10°C

- Explosion limits in air: 1 to 12.5 Vol. %

- Storage stability: 2 years after filling, if correctly stored

- Packaging materials: aluminum, HDPE, PP, and glass

Other Measures

It is well-suited for degreasing ACRYLITE® acrylic sheet surfaces prior to bonding. These are best wiped down with a clean white cloth or white paper towel soaked with ACRIFIX® TC 0030.

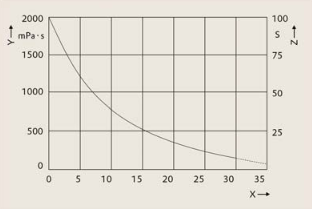

Viscosity of ACRIFIX® 2R 0190:

- X = Thinner concentration

- Y = Viscosity

- Z = Time/6mm cup

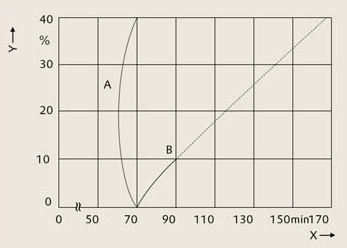

Influence of thinner concentration on polymerization time of ACRIFIX® 2R 0190 + 3% ACRIFIX® CA 0020 (on diluted adhesive):

Directions

Guidelines for Use

The viscosity of adhesives is adjusted so as to allow for their direct use. For certain applications, it is helpful to dilute the adhesives beforehand. Reducing their viscosity allows for the following:

- More rapid degassing because air bubbles rise to the surface quicker in diluted adhesive – advantageous for large quantities of the adhesive composition.

- Better leveling, thinner adhesive layers, and somewhat delayed skin formation – advantageous for bonding large surfaces (particularly of thin sheets) and drill holes.

- Better wetting out and degassing when embedding fiber mats and woven fabrics.

- More rapid filling of butt joints between thick blocks.

- Diluted adhesives enable shorter pot lives and polymerization times (at higher hardener concentration) because degassing and processing can be performed more quickly than with undiluted polymerization adhesives.

The viscosity required for a specific application must be determined by trial and error. In general, adhesives should be diluted as little as possible. The hardener concentration (e.g. ACRIFIX® CA 0020) depends on the quantity of diluted adhesive. The influence of the thinner on viscosity and polymerization can be seen in the corresponding charts.

Safety

Safety Measures and Health Protection

Contains methyl methacrylate. Irritates the eyes, respiratory system, and skin. May cause sensitization by skin contact. Keep away from sources of ignition. Do not smoke. Wear suitable protective gloves. Avoid contact with the skin. In case of swallowing seek medical aid immediately.