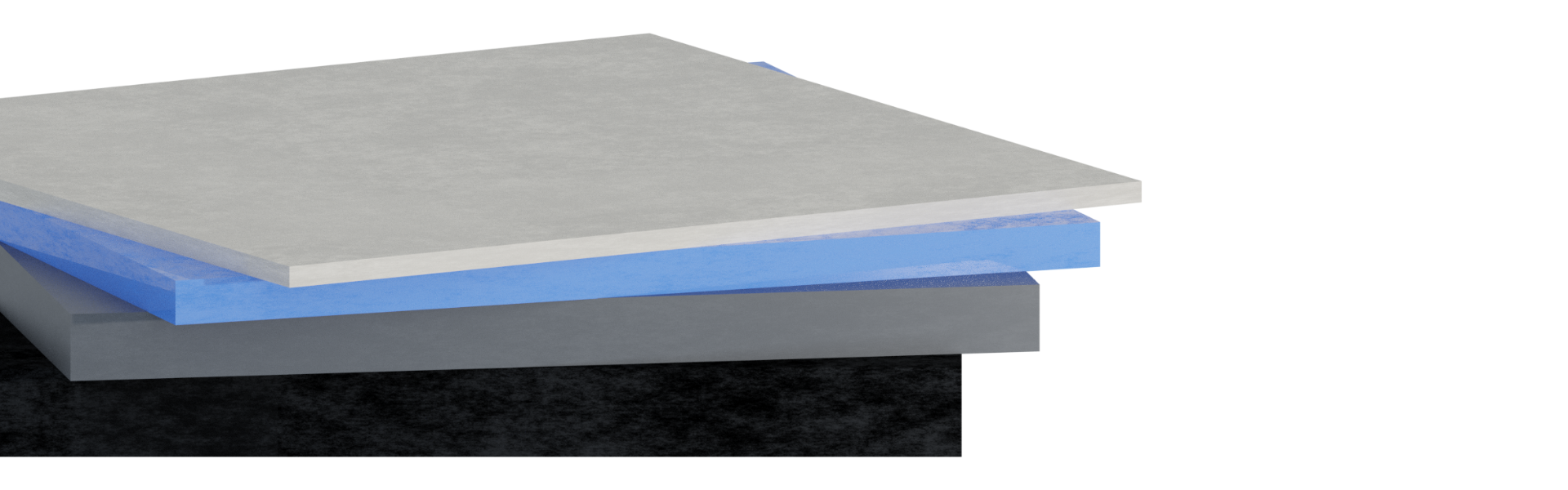

Nylon

Nylon

Nylon is a strong, stiff engineering plastic with outstanding bearing and wear properties. Nylon is frequently used to replace metal bearings and bushings often eliminating the need for external lubrication. Other benefits include a reduction in part weight, less operating noise, and decreased wear on mating parts.