Description

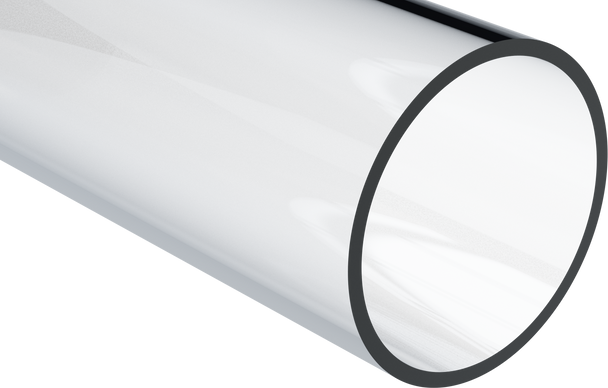

Polycarbonate, developed in 1953, is a highly durable plastic known for its exceptional strength and versatility. Our Polycarbonate Clear Round Tubes are perfect for projects where lightweight materials, high impact resistance, and a moderately clear appearance are desired. These tubes are easy to cut, machine, glue, and shape, making them ideal for product displays, scientific instruments, advertising, signage, and more.

Overview & Applications

Overview

Polycarbonate Clear Round Tubes are lightweight yet strong, offering superior impact resistance and good clarity. These tubes are electrically non-conductive, chemically resistant, and maintain excellent dimensional stability across a wide temperature range from -40°F to 280°F. Ideal for various applications including displays, signage, and scientific instruments.

Applications

Polycarbonate Clear Round Tubes are versatile and can be utilized in a variety of applications:

- Product Displays & Exhibits

- Scientific Instruments

- Advertising & Signage

- Crafting & Hobbies

- Custom Fabrication & Prototyping

- Protective Covers & Guards

- Architectural Elements

- Decorative Installations

Key Attributes & Specifications

Key Attributes

- Impact Resistance: 200x stronger than glass, 25x stronger than acrylic.

- Optical Clarity: Provides 88% light transmittance.

- Temperature Resilience: Performs across a broad range from -40°F to 280°F.

- Chemical Resistance: Higher resistance compared to acrylic.

- Non-Conductive: Electrically insulating, safe for various applications.

- Easy Fabrication: Can be easily cut, machined, glued, and shaped.

Technical Specifications

| Property | Value |

|---|---|

| Tensile Strength | 9,500 psi |

| Impact Strength | 13 ft-lb/in (Notched Izod) |

| Density | 0.043 lb/in³ |

| Water Absorption | 0.12% |

| Flexural Strength | 15,000 psi |

| Compressive Strength | 12,000 psi |

| Coefficient of Linear Thermal Expansion | 3.9 × 10⁻⁵ in./in./°F |

| Heat Deflection Temperature | 270°F (at 264 psi) |

| Dielectric Strength | 390 V/mil |

| Flammability Rating | H-B (V-0 at 0.45" thickness) |

Comparison & Installation

Material Comparison: Polycarbonate vs. Acrylic vs. Glass

| Feature | Polycarbonate | Acrylic | Glass |

|---|---|---|---|

| Impact Resistance | 200x stronger than glass | 25x stronger than glass | Breakable |

| Light Transmission | 88% (Good optical clarity) | 92% (Excellent optical clarity) | 88% (Good optical clarity) |

| Weight | Lightweight | Lightweight | Heavy |

| Temperature Resistance | -40°F to 280°F | -30°F to 170°F | 32°F to 212°F |

| Chemical Resistance | Higher resistance to chemicals | Moderate resistance | Low resistance to chemicals |

| Ease of Fabrication | Easy to cut, machine, glue, and shape | Easy to cut, machine, and shape | Difficult to cut and shape |

| Cost | Moderate | Lower | Higher |

Installation & Maintenance Tips

Installation

Polycarbonate Clear Round Tubes can be easily cut, machined, glued, and shaped with standard tools. For best results, ensure surfaces are clean and dry before installation. Use compatible adhesives and sealants for secure attachment.

Maintenance

Maintain the clarity and quality of your Polycarbonate tubes with simple cleaning using a soft cloth and non-abrasive cleaners. While these tubes offer good optical clarity, polishing is not recommended. Light scratches can be addressed using special abrasive compounds made for polycarbonate.

FAQs & Safety

Frequently Asked Questions (FAQs)

Q: How do I clean Polycarbonate tubes?

A: Use a mild soap and water solution with a soft cloth. Avoid abrasive cleaners as they can scratch the surface.

Q: Can Polycarbonate tubes be cut to custom sizes?

A: Yes, Polycarbonate tubes can be easily cut using standard tools. We also offer custom cutting services.

Q: Is Polycarbonate UV resistant?

A: Yes, Polycarbonate tubes are UV stabilized, making them suitable for outdoor applications.

Q: How does Polycarbonate compare to glass in terms of safety?

A: Polycarbonate is significantly safer than glass due to its high impact resistance. It is 200 times stronger than glass, making it shatter-resistant and ideal for applications where safety is a priority, such as in protective covers, machine guards, and structural components.

Q: Can Polycarbonate tubes be used in extreme temperatures?

A: Yes, Polycarbonate tubes are highly durable and can withstand a wide temperature range from -40°F to 280°F, making them suitable for both indoor and outdoor environments, including areas with extreme heat or cold.

Q: Are Polycarbonate tubes recyclable?

A: Yes, Polycarbonate is a recyclable material. It can be reprocessed and reused, contributing to sustainability efforts and reducing environmental impact.

Q: What are the common applications of Polycarbonate Clear Round Tubes?

A: Polycarbonate Clear Round Tubes are commonly used in applications that require high strength and optical clarity, such as display cases, architectural elements, scientific instruments, protective covers, and decorative installations. Their high-gloss finish and durability make them ideal for both functional and aesthetic applications.

Q: Can Polycarbonate tubes be easily machined?

A: Yes, Polycarbonate tubes can be easily machined using standard tools. They can be cut, drilled, and formed without cracking or breaking, making them ideal for custom fabrication and structural applications.

Q: Does Polycarbonate yellow over time?

A: Polycarbonate tubes are UV stabilized to reduce yellowing over time, making them suitable for long-term outdoor use where exposure to sunlight is a factor.

Q: How do Polycarbonate tubes handle chemical exposure?

A: Polycarbonate has good chemical resistance to many substances, but it is advisable to avoid exposure to certain chemicals, such as strong acids and bases, to maintain the material's integrity and appearance.

Safety & Handling Instructions

Handling: Polycarbonate is generally safe, but always use personal protective equipment such as gloves and safety goggles when cutting or machining to avoid dust and fumes.

First Aid:

- Inhalation: If inhaling dust or fumes, move to fresh air immediately. Seek medical attention if symptoms persist.

- Eye Contact: Flush eyes with water for at least 15 minutes. If irritation continues, consult a physician.

- Skin Contact: Wash affected areas with soap and water. If irritation occurs, seek medical advice.

- Ingestion: Do not induce vomiting; seek medical help immediately.