Description

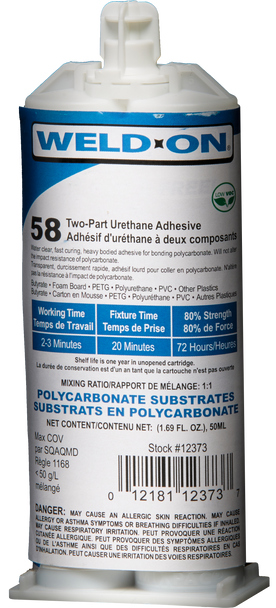

Weld-On 58 is a fast curing, clear colorless, two-component, 100% reactive polyurethane adhesive that contains no volatile organic compounds (VOC). When mixed and applied, it polymerizes at room temperature to form high bonds within a few hours. The adhesive has excellent resistance to discoloration by UV light and has excellent lap shear and impact strength.

Substrate Recommendations

Weld-On 58 is formulated for bonding a wide variety of thermoplastics, including polycarbonate, butyrate, PETG, anti static acrylic, ABS, PVC, polyurethane and foam board to themselves and one another.

Bonding Recommendations

Weld-On 58 is recommended for a variety of applications in the sign assembly industry, especially butyrate trim cap to polycarbonate in channel letter applications. It also has many uses in other plastic fabrication industries for bonding ABS to PETG.

Technical

Typical Bond Strength†

| Substrate Material | Aged Bond Strength, lbs/in2 (kg/cm2) | ||

| 24 Hours | 72 Hours | 1 Week | |

| ABS | 2,150 (151) | 2,300 (162) | 2,500 (175.8) |

| PETG | 1,600 (113) | 2,350 (165) | 2,400 (168.7) |

| Polycarbonate | 1,950 (137) | 2,650 (186) | 2,900 (204.0) |

† Substrate thickness: 0.25 inch (0.64 cm). Bond area: 1.0 in² (6.45 cm²). Ultimate Bond Strength is defined as strength achieved after 24-hour room temperature cure.

Adhesive Properties and Characteristics @ 73°F (23°C)

| Color | Clear |

| Viscosity | 3000 ± 1000 cps |

| Reactivity | Gel time = 2 Minutes, 50 Gram mass |

| Tack Free Time | 25 Minutes, .050 inch (0.13 cm) film thickness |

| Working Time | 5-6 Minutes |

| Fixture Time (Time to reach 80% of ultimate strength) | 20 Minutes |

| Time to reach Ultimate Bond Strength | 2 Hours |

| Specific Gravity (g/cc) | Component A: 1.166 ± 0.004 Component B: 1.123 ± 0.004 |

| Coverage | 10 mil: 3 sq ft/cartridge 20 mil: 1.5 sq ft/cartridge |

Directions

Directions for Use

Weld-On 58 is packaged in a twin-syringe cartridge with 50 ml total capacity that dispenses product in a 1:1 mix ratio. The package is designed for use with the MIXPAC 50 dispensing gun. The syringe and gun employ the supplied static mixing nozzle that mixes the product as it travels the length of the mixer from the syringe to the tip of the nozzle. See the mixing instructions included in the adhesive package.

- Be sure that both adhesive components are flowing freely from the cartridge before attaching the mixing nozzle. When using the mixing nozzle for successive applications, renew the adhesive in the nozzle by extruding and discarding a few inches of the material prior to application to the bonded assembly.

- If the mixing nozzle is left on the cartridge for a sufficient length of time without additional use, the adhesive may cure in the nozzle. If this happens, keep the mixing nozzle on the cartridge until you are ready to dispense more adhesive at which time you will need to put a fresh mixing nozzle on the cartridge. Be sure to discard the first few inches again.

NOTE: The viscosity of this product will allow it to flow between the polycarbonate letter and the butyrate trim cap in most channel letter applications. The application of a reinforcing bead is recommended.

Shelf Life

Keep away from sources of heat, open flame, sparks, sunlight and moisture. Do not store in upper levels of non air-conditioned warehouses. Shelf life is one year in unopened pouch under these conditions.

Safety

Safety and Environmental Precautions

Weld-On 58 is a reactive adhesive and is classified as a hazardous material. This product does not emit VOC. In conformance with the Federal Hazardous Substrates Labeling Act, the following hazards and precautions need to be recognized and followed.

WARNING! CONTAINS ISOCYANATE. VAPOR HARMFUL. MAY BE HARMFUL IF SWALLOWED. MAY IRRITATE SKIN OR EYES.

Keep out of the reach of children. Do not take internally. Keep away from heat, spark, open flame and other sources of ignition. Contact with hot surfaces may produce toxic effects. Keep container closed when not in use. Store away from direct sunlight between 50º F – 80º F (10º C – 27º C). Use only in adequate ventilation. Avoid breathing of vapors. Atmospheric levels should be maintained below established exposure limit values. See Sections II and VIII of Material Safety Data Sheet. If airborne concentrations exceed those limits, use a NIOSH-approved organic vapor cartridge respirator with full face-piece for single short- term exposure. For emergency and other conditions where short-term exposure guidelines may be exceeded, use an approved positive pressure self-contained breathing apparatus. Do not smoke, eat or drink while working with this product. Avoid contact with skin, eyes and clothing. May cause eye injury. Protective equipment such as gloves, safety goggles and impervious apron should be used. Carefully read Material Safety Data Sheet and follow all precautions. Contents are non-hazardous and not regulated. Do not use this product for other than intended uses.

First Aid

Inhalation: If overcome with vapors, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Call physician.

Eye Contact: Flush with plenty of water for 15 minutes and call a physician.

Skin Contact: Wash skin with plenty of soap and water for at least 15 minutes. If irritation develops, get medical attention.

Ingestion: If swallowed, give 1 or 2 glasses of water or milk. Do not induce vomiting. Contact physician or poison control center immediately.