Description

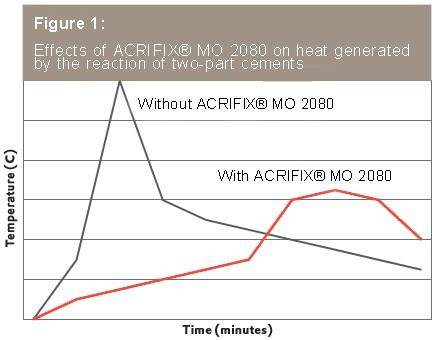

ACRIFIX® MO 2080 is used to slow down the polymerization reaction of our reactive cements. It moderates the heat generated during the curing process and resolves bubbles and crazing issues. When used with a two-component polymerization cement such as ACRIFIX® 2R 0190 or ACRIFIX® 2R 0195, cement joints become practically invisible.

- 2 oz dropper bottle

- Slows down the polymerization reaction

- Developed for ACRIFIX 2-part reactive cements

Commonly used for applications such as:

- Museum-quality vitrines

- Display cases

Technical

Two-Component Cement

Two-component cement should be used when strength, resistance to environmental conditions, and high optical appearance is required. They also fill better and impose fewer demands on the accuracy of fit between the parts.

Two-component cement consists of polymers dissolved in monomers (Part A) which cure when a catalyst or hardener (Part B) is added. They are also referred to as two-part cement. The cure, or hardening of the cement mixture, is brought about by a chemical reaction. As a result of the chemical reaction the cement mixture shrinks and heats up as it cures. This can often result in the formation of bubbles or “pull back” of the cement from the edges of the joint. The proprietary formulation in ACRIFIX MO 2080 eliminates or reduces these defects.

Directions

Workshop & Equipment

The following equipment and conditions should be considered when using polymerizable cement:

- Flat Working Surface: Cover work area with glass or polyester film. Vapor removal is necessary. Solvent vapors are heavier than air.

- Weighing Scale: The scale should have an accuracy of about one gram for weighing out the cement.

- Mixing Vessels: Use round beakers made of glass, polyethylene, or other materials which are insoluble and do not swell.

- Stirrer: Stir small amounts with glass or polyethylene insoluble rods.

- Vacuum Chamber: A small metal, glass, or plastic chamber that can hold a beaker cement and is capable of withstanding a vacuum of 3 psi.

- Vacuum Pump: A small vacuum pump capable of evacuating the above chamber to a vacuum of 3 psi.

- Syringes: Disposable syringes for applying the cement.

- Jigs & Fixtures: For mass production, it is advisable to use gluing jigs which can be used repeatedly. Parts can be attached with clips, clamps, lead weights, or vacuum.

- Sealing & Spacing: Use polyester tape to contain the cement.

Mixing Procedure

Follow instructions for the mixing ratios of the two-part cement. For 100 grams of ACRIFIX® 2R 0190 or ACRIFIX® 2R 0195 (Part A) and 5 grams of ACRIFIX® CA 0020 (Part B) add 0.12 grams (6 drops) of ACRIFIX® MO 2080. Adjust ratio for different size batches (example: Use 3 drops with 50 grams of “Part A” and 2.5 grams of “Part B”).

In some cases a product like ACRIFIX® TC 0030 Thinner and Cleaner can be used to reduce the viscosity of the cement mixture to allow the material to flow into the joint better. The recommended amount of thinner is up to 10% by weight of the mixture. Fully stir the mixture for 1 to 2 minutes.

The mixture should be degassed using one of the following techniques before applying adhesive to the joint.

- Place it in a vacuum chamber for 3 to 5 minutes or until the bubbles have disappeared

- Centrifuge the mixture for 3 to 5 minutes or until all the bubbles have disappeared

- Allow entrapped air bubbles to rise to the surface in a covered container

When the two-part cement is ready, apply the mixture to the joint. Wait for the material to be fully cured before attempting to move the acrylic. Premature movement of the acrylic can cause quality issues. ACRIFIX® MO 2080 may double the typical pot life from 20 minutes to 40 minutes.

Safety