Crafting Watertight Custom Acrylic Tanks for Film Sets

Behind the Scenes: Crafting a Watertight Custom Acrylic Tank for Film and Theater

The Vision and Design

Creating a custom acrylic watertight tank requires precision, creativity, and advanced engineering. Our journey began with a vision—a concept that needed to transition seamlessly from design to reality. The goal was to craft a tank that not only met the visual and functional needs of the production but also adhered to stringent safety and durability standards essential for on-set use.

Calculating Acrylic Thickness

A crucial step in designing a watertight tank is determining the appropriate acrylic thickness, which depends on the tank's dimensions and the water pressure exerted on its walls. Water pressure increases with depth, so taller tanks require thicker acrylic to withstand the force.

To calculate the necessary acrylic thickness, here’s a simplified formula we use:

Step 1: Calculate Water Pressure

- Water height (H): Measure the height of the water column in inches.

- Water density (ρ): Use 62.4 lb/ft³ for freshwater or 64 lb/ft³ for saltwater.

- Gravitational force (g): Use 32.2 ft/s².

The water pressure at a given depth is calculated as:

P = H × ρ × g

where P is in pounds per square foot (PSF) if all units are consistent.

Step 2: Factor in Safety

Aquariums typically require a safety factor to account for additional forces (like a fish bumping into the wall). A common safety factor for acrylic aquariums is 2 or 3.

Step 3: Calculate Acrylic Thickness

The thickness (T) of the acrylic depends on the water pressure and tank length. A simplified formula to estimate acrylic thickness for aquariums is:

T = (L × H × SF) / 4000

- L = Length of the tank in inches

- H = Height of the tank in inches

- SF = Safety factor (typically 2 or 3)

The result (T) will be in inches.

Example Calculation

For a 24-inch tall, 36-inch long aquarium with a safety factor of 2:

Plugging in values: T = (36 × 24 × 2) / 4000 = 0.432 inches

You’d want at least 0.5-inch thick acrylic, as 0.432 inches is a minimum estimate.

The Building Process

Once the specifications were finalized, our skilled team of fabricators began preparing materials and planning the assembly. Using thick, clear cast acrylic sheets, we meticulously cut and shaped each component with a CNC router. The pieces were then bonded using high-strength, two-component acrylic adhesives like Weldon 42 and Acrifix 0190, which ensure bubble-free joints that are watertight and robust.

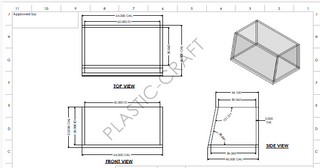

CAD Design and Assembly

Each component was designed with CAD software, allowing us to calculate exact measurements and alignments. The assembly phase involved detailed measuring, alignment, and hand-finishing to give the tank its crystal-clear appearance. In our state-of-the-art workshop, equipped with advanced machinery, we carefully polished the edges to ensure a flawless finish, giving the tank a sleek and polished look that’s camera-ready.

Overcoming Challenges

Every custom project presents unique challenges. For this tank, a major challenge was ensuring that it could handle the immense weight and pressure of being filled with water while remaining perfectly clear and visually seamless. To overcome this, we reinforced key structural areas and used advanced bonding techniques to achieve both strength and visual clarity. With this approach, we produced a tank that’s not only flawless but also strong enough for multiple uses across film and theatrical productions.

The Result

The final result was nothing short of impressive: a sleek, high-quality acrylic tank ready for its cinematic debut! Whether it’s featured in a dramatic underwater scene or as a captivating stage prop, this tank is designed to catch the eye and elevate the storytelling experience.

Why Choose Plastic-Craft for Custom Projects?

Projects like these highlight why Plastic-Craft is a trusted partner for custom fabrication across various industries, from film and theater to commercial and residential installations. Our commitment to quality, attention to detail, and passion for problem-solving are unmatched, backed by over 80 years of experience in custom fabrication.

Contact us today to bring your unique project to life or learn more about our custom solutions. We’d be delighted to help turn your vision into reality!

Recent Posts

-

Essential Material Properties Glossary for Plastics

Comprehensive Material Properties Glossary Welcome to the ultimate guide for understanding material …Nov 27th 2024 -

Precision Gun Drilling in Clear Cast Acrylic Rods

Precision Gun Drilling in Action: Crafting a 1" Clear Cast Acrylic Rod with a 0.375" Central Hole …Nov 8th 2024 -

Crafting Watertight Custom Acrylic Tanks for Film Sets

Behind the Scenes: Crafting a Watertight Custom Acrylic Tank for Film and Theater The Vision and De …Nov 7th 2024